ARMOR SMART FILMS equips itself to industrialise the production of intelligent piezoelectric films

ARMOR SMART FILMS has recently acquired new large-format flat screen printing equipment. Having been involved in this printing process - flat or rotary - for many years, this investment will enable the company to strengthen its expertise in the design and production of intelligent films, such as electro-active films (particularly piezoelectric), for the development of projects involving sensors or energy storage, for example.

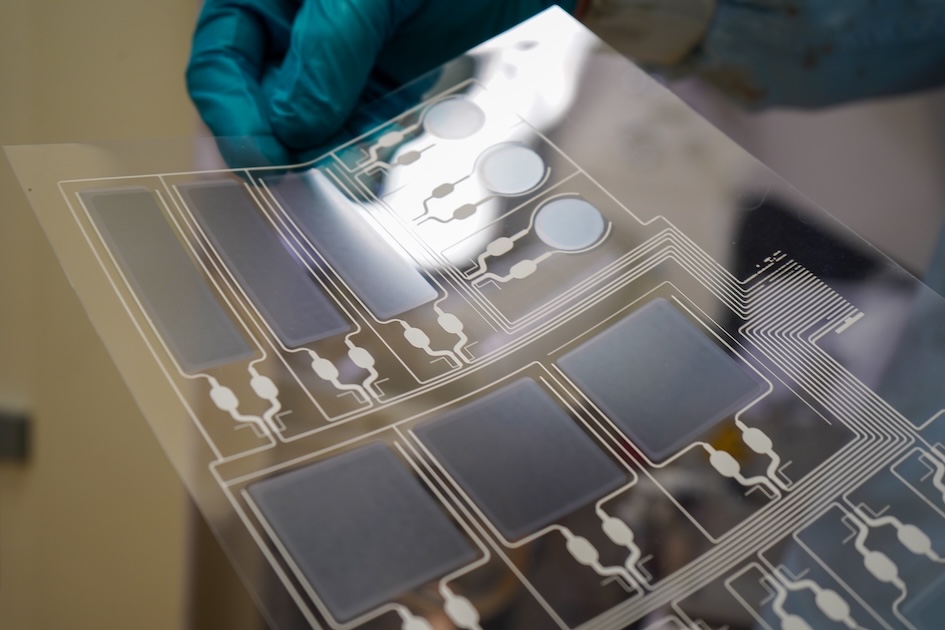

New flat screen printing equipment for ARMOR SMART FILMS

Over the years, ARMOR SMART FILMS has developed particular expertise in printing solutions for complex active materials, particularly multi-layers. To develop this expertise in volume, but also to be able to print on rigid substrates or in sheet format, the company has just acquired a new large-format flat screen printing machine - a printing technique based on the use of screens, enabling motifs to be printed with a high level of definition. Equipped with a drying tunnel and capable of printing media as large as one square metre at high speed and with great precision, this new equipment means that ARMOR SMART FILMS can now screen print very large volumes of intelligent surfaces. The machine also complements the company's existing A4 and A3 flatbed screen printers. These small-format printers are used in particular for exploratory work and prototyping. With this equipment, ARMOR SMART FILMS now has small, medium and large-scale flat screen printing capacity.

‘In an increasingly connected world, the demand for sensors is exponential. The specificity of flat screen printing means that several layers can be superimposed, enabling the production of complex, patterned active devices such as sensors. Until now, our capabilities have been on an industrial scale for rotary printing, but on a laboratory and pilot scale for flat screen printing. With this new equipment, we're moving up a gear,’ explains Pierre Guichard, CTO of ARMOR SMART FILMS.

Expertise in piezoelectric film printing

The arrival of this new screen-printing equipment is in line with ARMOR SMART FILMS' development in the design and production of electro-active films, materials which have the ability to generate an electrical charge in response to an applied mechanical stress, and vice versa. Given the existing demand for this technology, ARMOR SMART FILMS has embarked on a number of projects incorporating these piezoelectric films. ‘We are currently working on connected soles in which we screen-print a network of sensors that follow the shape of the foot, offering a range of uses: medical, to manage diabetes for example, and sporting, to analyse stride or posture,’ explains Pierre Guichard. He continues: ‘Our films also have industrial applications. Proof of this is the production of seals for fuel cells in hydrogen-powered vehicles, which require the printing of discontinuous shapes that flat screen printing is perfectly capable of producing in mass production.’

ARMOR SMART FILMS in growth

Officially launched in early 2024, ARMOR SMART FILMS designs and produces smart films, materials designed to be sensitive, adaptive and scalable. Its prospects for industrial and commercial development are encouraging, with applications linked to presence sensors, transducers or membranes for energy storage or production, desalination, carbon capture or the production of hydrogen by electrolysis. ‘ARMOR SMART FILMS offers three complementary levels of service: R&D, prototyping and large-scale production. Confident about our development, we are now aiming to triple our current sales by 2027,’ says Pierre Guichard. On the team side, ARMOR SMART FILMS has a dozen dedicated employees and is looking to expand its team by recruiting three new R&D staff. This is the first round of recruitment, with more to come.