The new ARMOR BATTERY FILMS factory opens its doors to the MEDEF

On Tuesday 11 June, Patrick Martin, President of MEDEF (Mouvement des Entreprises de France), and a delegation of the organisation's local and national representatives were given a sneak preview of the new ARMOR BATTERY FILMS plant. With this new site at La Chevrolière, ARMOR GROUP is developing a new model of aluminium and copper foil, essential for battery operation.

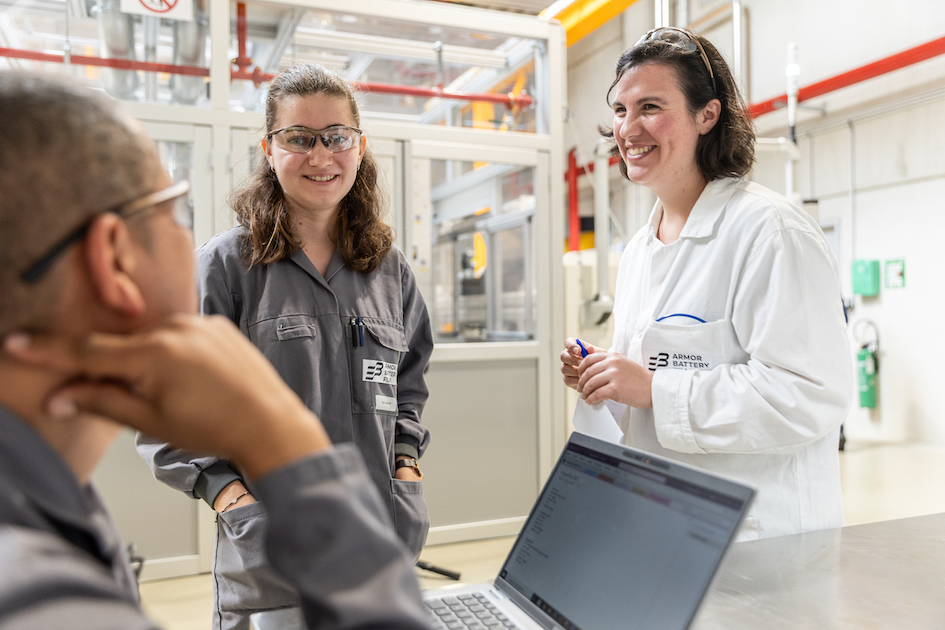

After work began in January 2023, ARMOR BATTERY FILMS gave a preview of its coated current collector reel production plant to Patrick Martin, Chairman of the MEDEF, and his delegation in June. The visit took place in the presence of Hubert de Boisredon, Chairman and CEO of ARMOR GROUP, and Christophe Derennes, Industrial and Operations Director of ARMOR GROUP.

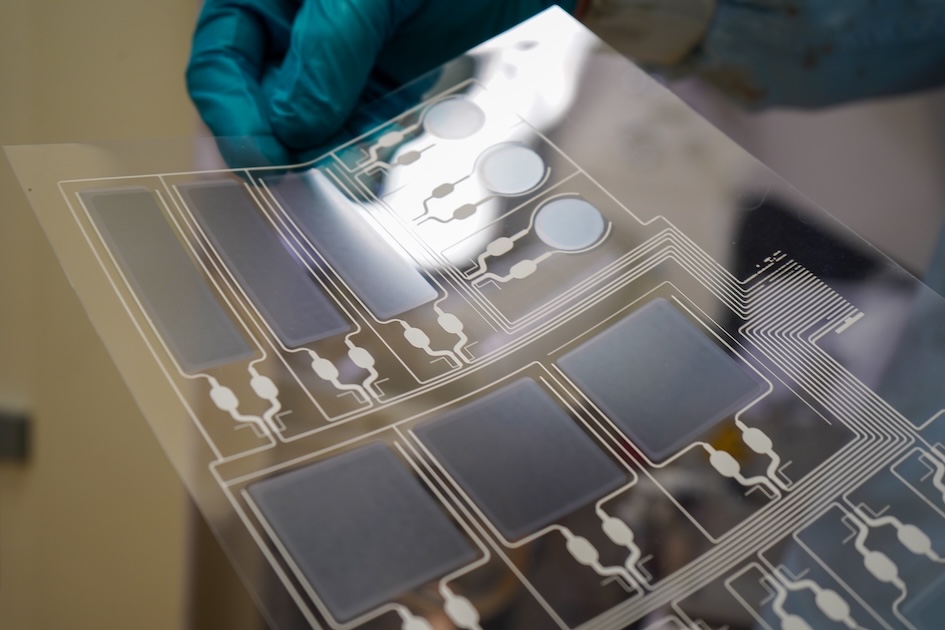

Current collectors are essential membranes for the smooth operation of lithium-ion batteries, which are ubiquitous in everyday life. They power everything from mobile phones to electric cars. These innovative collectors increase battery life by 20% and charge them twice as fast. Another major advance is that, with these new-generation foils, the corrosion and flammabilitý of batteries are reduced, for greater safety.

This major project has a dual objective: to acquire new R&D resources and to increase initial production capacity fivefold, to 150 million m2 coated per year. This capacity would be enough to produce the equivalent energy from the 50 KWh batteries of 800,000 electric vehicles.

ARMOR BATTERY FILMS targets specific markets where demand for advanced battery solutions is growing rapidly, namely Europe, North America and Asia. ARMOR BATTERY FILMS' essential lithium-ion battery components are used in a variety of applications, such as eBuses, electric vehicles, data centres, and networked energy storage.

The MEDEF delegation visited the plant, which is equipped with three specialised laboratories: a formulation laboratory, a characterisation laboratory and an electrochemical laboratory, part of which is in an anhydrous room. The €37m investment, the largest ever made by ARMOR GROUP in one go, is helping to structure the battery industry in France and contribute to the country's re-industrialisation. "Ensuring a complete value chain for battery manufacturing in Europe is a key strategic challenge for the continent's competitiveness and energy resilience, as well as its re-industrialisation," says Hubert de Boisredon. "Small and medium-sized businesses are agile companies that have the resources to invest. Supporting them is a strategic challenge," he concludes.